By Gabriel Scotto / Woub

PIKETON, Ohio (WOUB) — After undergoing 13 years of cleanup, a former uranium enrichment plant in Piketon is being repurposed as an alternative energy hub and manufacturing facility.

As part of these efforts, Texas-based Newpoint Gas is investing $1.5 billion in a facility that will convert natural gas into hydrogen.

Completed during the Cold War, the Portsmouth Gaseous Diffusion Plant enriched thousands of tons of weapons-grade uranium for atomic bombs, along with low-enriched uranium for use as fuel in commercial nuclear reactors. Uranium enrichment at the plant ended in 2001.

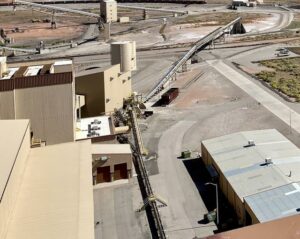

The sun sets over the Portsmouth Gaseous Diffusion Plant in Pike County, Ohio on May 6, 2019. [Jordan Kelley | WOUB]

“Pretty much unanimously, it was about ‘jobs, jobs, jobs.’ Because it was a major employer for so many decades, they wanted to see the site leveraged for additional jobs for the future,” said Stephanie Howe, director of energy programs at the Voinovich School.

Howe and the Voinovich School found the top three preferred uses for the plant of those surveyed were energy production, manufacturing and research and development. Eventually, the decision was made to pursue an “all of the above” strategy, focusing on decarbonization through producing nuclear and green energy and engaging in sustainable manufacturing. Other goals of the project include onshoring vital supply chains and investing in union labor.

“We have a partnership with organized labor in the state of Ohio and we’re getting the developers we’re working with to sign agreements where they use union labor for these projects,” Howe explained. “Because if you’re using union labor and growing union jobs, that’s going to grow the middle class.”

Newpoint Gas’ facility in Piketon will convert natural gas into 500 metric tons per day of hydrogen that will be used in the production of clean ammonia and clean silicon for use in the production of steel, aluminum, solar panels and semiconductors.

While Newpoint will initially produce hydrogen using natural gas as the feedstock, this is not intended to be a permanent arrangement. Rather, it represents an early stage in hydrogen production before the technology matures and becomes widespread.

“In order to launch the hydrogen economy, you have to create this foundation of hydrogen production and hydrogen infrastructure,” said Wiley Rhodes, CEO of Newpoint. “The long-term objectives are to be able to replace that at some point in the future whenever the technology and economics will support it to use water and other components as the feedstock to produce the hydrogen.”

To convert natural gas into hydrogen, Newpoint will separate the carbon atoms from the hydrogen atoms using a steam methane reformer, with the resulting carbon dioxide being sequestered underground.

In addition to natural gas being readily available, another factor behind Newpoint’s decision to construct this facility in Piketon is because the unique geology of Appalachia makes southeastern Ohio ideal for sequestering carbon.

“We’re taking the natural gas, bringing it into a system and then we’re putting the carbon back where it comes from. There’s underground caverns and formations that are conducive to storing gaseous molecules,” Rhodes explained. “There’s enough storage capacity in southeastern Ohio that we can get started (in sequestering carbon).”

Newpoint will be the second energy company to establish operations at the plant in Piketon. In mid-October, Maryland-based Centrus Energy began producing high-assay, low-enriched uranium (HALEU) for next generation nuclear reactors and modular nuclear reactors.

Another energy firm, California-based Oklo, is planning on constructing two nuclear power plants at the Piketon site that will utilize the HALEU produced onsite by Centrus. In addition, plans are being made by an as-yet-unnamed energy company to construct large-scale battery storage for electricity generated by solar arrays.

Howe says that the goal of these projects is to get more clean energy onto the national grid.

“Right now, people are talking about ‘electrify, electrify, electrify,’ but just because you plug something in doesn’t mean it’s clean. Something has to produce the electricity,” Howe said. “We’re really looking at how do we get more cleaner power available for industry as well as just residential consumers.”